Food Waste: The Opportunities and Challenges of Selling Loose

Most surveys on the location of food waste suggests that a significant, if not the majority of food waste occurs in the consumers home, the consumer either prepares too much food, the goods expire before they are cooked, eating plans change, etc. Advocates for food waste reduction believe that consumers often buy too much and more than they need because they are only available in bags, plastic boxes, nets, etc. In the UK, advocate and TV celebrity Gino D'Acampo, featured in an advertising campaign, part of the UK Food Waste Action week.

In a recent meeting, the retailers in the food waste working group discussed the good, bad and ugly of selling loose. Below are three key takeaways from the discussion, attended by over 50 retailers from the working group.

Takeaway #1: Really?

There was a lot of discussion in the group as to whether the promotion of selling loose was a strategy would lead to a change in shopper behaviour, there are good reasons, such as hygiene and convenience of handling, why consumers choose packed, bagged and netted products. There was also discussion as to whether there would be a reduction in the quantity of food wasted in the consumers home, nearly a quarter of the food wasted in the home was thrown away after being cooked. Finally, there was discussion on convenience, for many time conscious shoppers the convenience and ease of being able to just pick up (say) a bag of potatoes beats having to pick your own potatoes, put them in a bag, weigh them and apply the label. Net, the consensus in this meeting at least, was that the the case for change had not been proven.

Takeaway #2: Selling Loose Increases Food Waste in Retail?

Bags, nets and packages were created for good reasons, they can often increase the shelf life, they reduce the damages and the spoils from handling, in the home, in the store, and across the whole supply chain. They also help provide the shopper with assurances of quality and when stock is low, it reduces the presentation of just the rejected "ugly" products [that most often at best get donated, at worst, thrown away]

Through a productivity lens, replenishing and presenting loose is more time intensive for store associates. Then, for online orders, pickers picking an order of (say) 1 kg of loose onions can take 4X the time they would take to pick a 1kg bag of onions.

Finally, at the checkout, scanning loose products requires the items to be "looked up" on a product menu, and then the quantity to be inputted or weighed, This takes seconds when checking out via a staffed lane but via self-checkout, can take significantly more time and inevitably lead to mistakes and the temptation to not scan. Typically, most multiple supermarkets now sell more carrots and brown onions than they have ever had delivered!

Net, while loose will make the fresh area more attractive and add some "theatre" to the shopping experience, there are a lot of operational complexities and extra costs associated with selling loose, with a greater risk of damage and waste, which at the least, will require a discount to sell.

Takeaway #3: Product Recognition Tech to the Rescue?

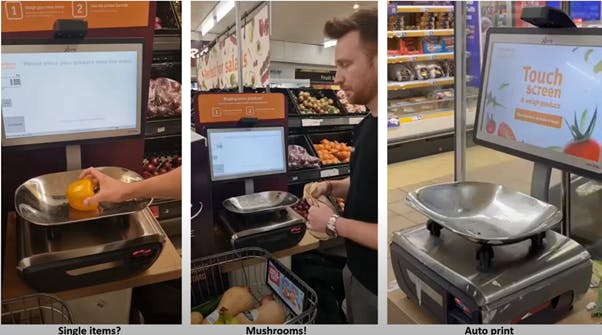

One retailer shared with the group their trial results from the use of "smart" product recognition scales that they have deployed in the produce aisle. Note, we also learnt in the meeting that other retailers had also installed these smart scales at the Self Checkout.

In the trials, after assurances on accuracy, the scales were found to be 99% accurate, the retailer shared that in silent mode, the scales observed that 4% of the labels printed were "wrong" in that the products presented did not match the label printed. In some cases, this was a simple mistake, for example, shoppers just pressed the easiest button to reach. In other examples, the mistake was perhaps more than a mistake. Encouragingly, when they moved to active mode, the error rate then went down from 4% to less than 1%.

But most impressively, they learnt that the time taken for the shopper to place the products on the scales, select the item, type in the quantity and put the label on the bag, was reduced by 85%.

The seal on the business case was made on the time savings for their online pickers and their improved productivity.

To learn more about what was discussed in the meeting, please see recap video with Richard Thalemann, our special advisor on food waste.

Next Food Waste Meeting - June 12th

Join us to learn about the latest thinking on markdown strategies, and new ways to optimise the process.

CLICK TO REGISTERMay 4, 2024

Main office

ECR Community a.s.b.l

Upcoming Meetings

Our Latest news

Join Our Mailing List

Subscribe© 2023 ECR Retails Loss. All Rights Reserved|Privacy Policy